Log In

Training

Tutorial

Article

Programming with the robot’s PROFINET IO Device Function

Core

60 min

In this course, you will learn how to program with the PROFINET IO Device function.

1. Getting Started

PROFINET is one of the industrial Ethernet protocols led by industrial equipment manufacturing companies such as Siemens, GE, etc, to accurately exchange data between manufacturing tools.

Doosan robot provides PROFINET IO Device function (robot information monitoring, General Purpose Register) through software without a separate HW device.

- Supported for: SW version M2.3.1 or later

This course will introduce programming with the PROFINET IO Device function provided by Doosan robot.

2. Preparation

This step introduces how to connect the representative PROFINET support device, PLC of German Siemens, and Doosan robot.

Requirements

- Computer with Siemens PLC (ex. S7-1200 etc) & TIA Portal installed

- Doosan Robotics collaborative robot M1013

- Setting File: GSDML.zip, pnio_io_table.pdf, DoosanRobot_PNIO.udt (downloadable on Robot LAB)

When the Doosan robot is booted, the PROFINET IO Device function is automatically executed during controller boot-up. Therefore, there is no additional set up needed on the robot or the Teach Pendant.

- The robot’s network settings can be used for normal TCP/IP communication and are independent of PROFINET communication.

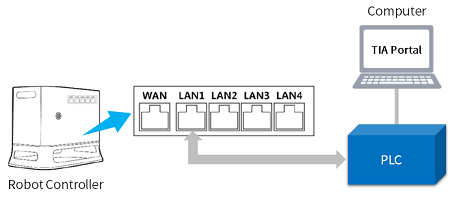

The PLC, robot, and computer connection for PROFINET communication is as follows.

3. Connecting Doosan Robot and PLC

3.1 Create a new project and move to the Project View Menu.

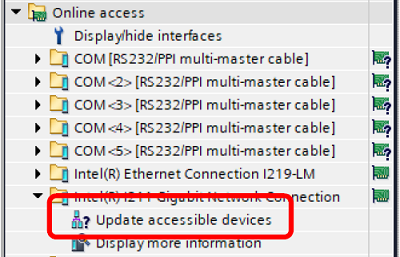

3.2 Move to the right Device Tree of TIA Portal and select Online Access – (used Ethernet interface) – Update accessible devices, and search new device.

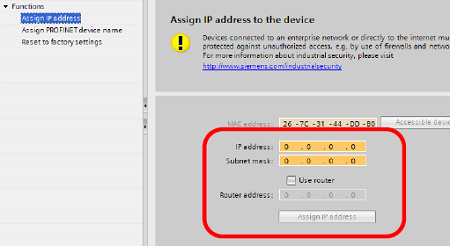

3.3 Select Online & diagnostics from the detected Accessible device (Doosan robot) and set up the following.

- Assign IP address: Enter the IP information you want to use (recommended for the same band value as PLC: 192.168.137.xxx)

- Assign PROFINET device name: Enter as “Doosan-robot”

3.4 Set up the prepared PLC similarly.

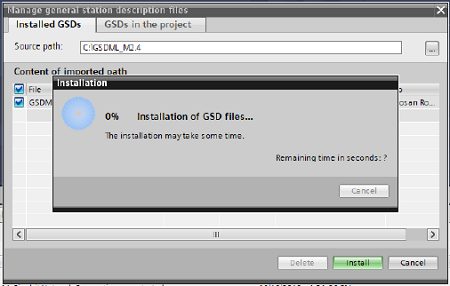

3.5 Install the GSDML file of Doosan robot prepared by the TIA Portal.

3.6 In Add new device, add the prepared PLC model and add ‘Doosan-robot’.

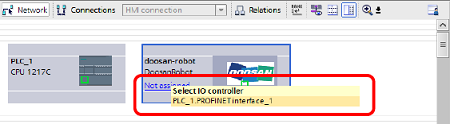

3.7 In the Device & networks window, click ‘Not assigned’ in the ‘Doosan-robot’ category and assign a PLC.

3.8 Set up each IP information of ‘Doosan-robot’ and PLC.

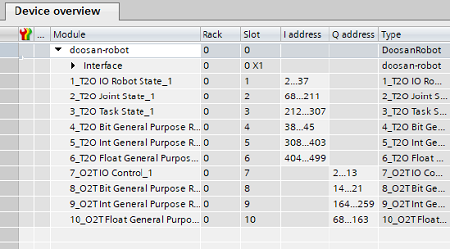

3.9 Add the I/O module required for ‘Doosan-robot’.

- The I/O module here is data provided by Doosan robot and more detailed information is available in pnio_io_table.pdf .

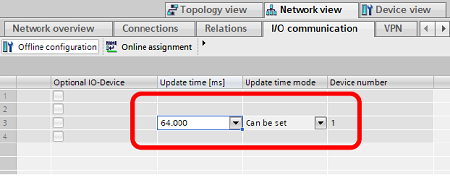

3.10 Modify the update time in IO Communication of Network View.

- Enter the value as 64 ms or bigger.

3.11 Compile the set project and download on PLC.

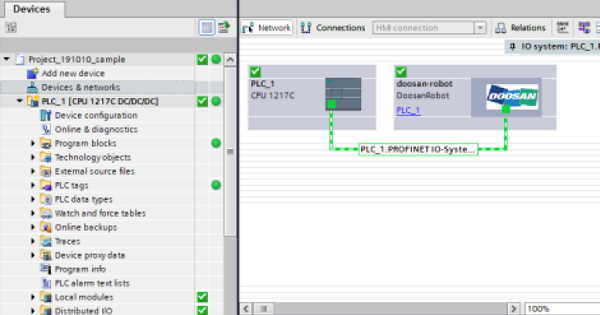

3.12 Finally, press the Go Online button and check the condition of the PLC and robot connection.

4. Retrieve Robot Information from PLC

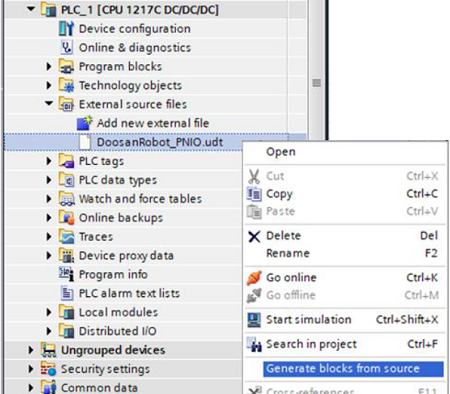

4.1 Retrieve the prepared DoosanRobot_PNIO.udt file in the External source files category of PLC.

4.2 Select the added DoosanRobot_PNIO.udt file and execute the Generate blocks from source function to add data type.

4.3 The Swap function of Program blocks must be used in order to verify the correct value for 4 byte data provided by Doosan robot. The type of the 4 byte data can be checked in pnio_io_table.pdf .

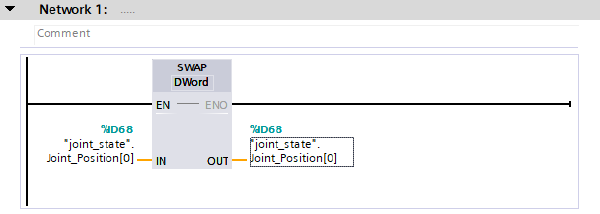

5. Using GPR on the Robot

The DRL commands below can be used in the task programming environment (Task builder, Task writer) to retrieve or modify the set register value.

- set_output_register_bit(address, val)

- set_output_register_bit(address, val)

- set_output_register_int(address, val)

- set_output_register_float(address, val)

- get_output_register_bit(address)

- get_output_register_int(address)

- get_output_register_float(address)

- get_input_register_bit(address)

- get_input_register_int(address)

- get_input_register_float(address)

These commands can be used in the IF statements or Custom Code commands, etc.

6. Summary

This course introduced the set up and programming required to use the PROFINET provided by Doosan robot. Please refer to the Installation or Programming manuals for more detailed information such as the commands for programming and some examples.

Recommended resources

- SIEMENS TIA Portal, https://new.siemens.com/global/en/products/automation/industry-software/automation-software/tia-portal/software.html

- Doosan Robotics Installation & Programming manual, https://robotlab.Doosanrobotics.com

※ Doosan Robotics has copyright and intellectual property rights to all content and all designs shown in this material. Therefore, any use, copying, or dissemination of them without written permission from Doosan Robotics is prohibited. Please note that you will be held solely responsible for any improper use or alteration of the patent rights of Doosan Robotics.

Recommended Training Class

These learning opportunities can help you get started quickly.

Article

How to program with EtherNet/IP

Article

How to program using TCP/IP Socket

Article

How to program using Modbus-TCP