Log In

Training

Tutorial

Article

Introduction to Safety-Related Features - Part 2. Work Space Setting and Troubleshooting Mode

Basic

60 min

In this course, you will learn about Doosan robot’s safety-related features regarding work space setting and troubleshooting mode.

- 1 . Getting Started

1. Getting Started

A collaborative robot is a robot that can be used without a fence in the same space as a worker. Therefore, features related to the safety of workers, robots, and work spaces are very important.

In addition to safety-related electrical interfaces, Doosan robot can use software to set up the robot's work space and maximize the safety functions as required, while efficiently configuring work. It also provides a troubleshooting mode that allows the robot to be manipulated in the event of a problem that may occur during robot use.

This course will introduce Doosan robot’s safety-related features such as work space setting and troubleshooting mode.

※ Precautions for safety-related features

- Set up a workcell using the robot’s safety-related functions and interfaces according to the risk assessment performed by the system integrator in regard to the robot’s application. For the information necessary for this process, please sufficiently acquaint yourself with Doosan Robotics Installation and User manual and consult it.

- When the robot’s safety system has found a system fault (when a wire breakage has occurred in the emergency stop circuit), when the position sensor has been damaged, or when a hardware abnormality such as a failure with control-purpose communication has been detected: stop category 0 starts immediately. When the robot’s safety system detects a violation during the execution of safety monitoring (when the emergency stop switch has been pressed), when a protective stop signal has been inputted, when an external shock has been detected, or when a physical parameter such as the robot’s position, speed, or momentum has exceeded its set limit: the robot is stopped according to the stop mode specified in the Safety settings menu. (Select one from among stop categories 0, 1 and 2)

2. Work Space Setting

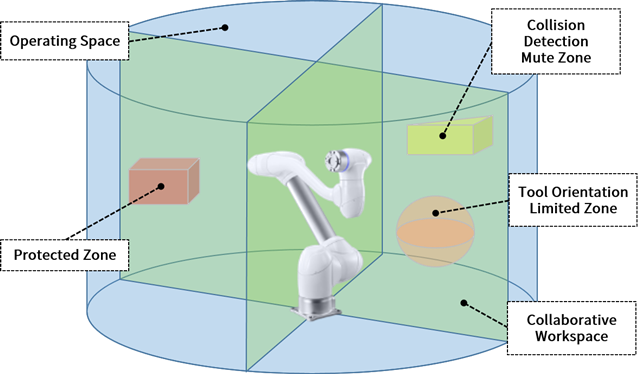

Doosan robot provides 5 types of work space setting functions, which can be used to not only increase work efficiency but also prioritize worker’s safety.

The different types of work spaces and set up methods are as follows.

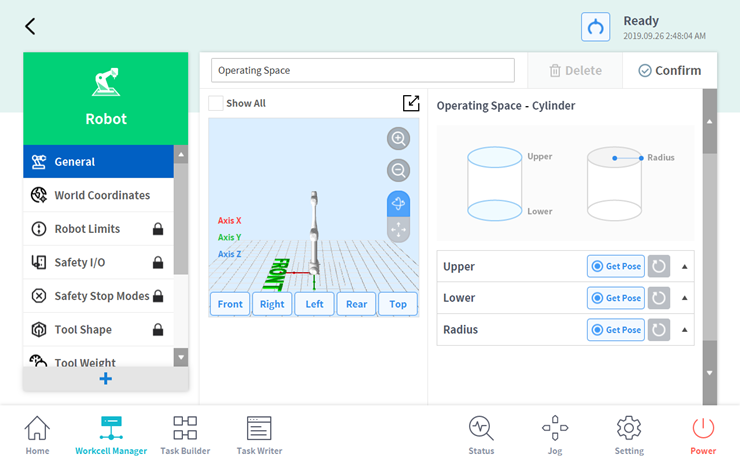

2.1 Operating Space: In a work space where robots operate, when teaching the robot by hand guiding, a repulsive force may be experienced if the robot reaches the work space boundary. If the robot moves out of the operating space during jog or robot automatic operation, the robot stops according to the safety setting set in the main menu.

[Try it]

In Work Space setting, set the geometry type as cylinder and then enter the point for the upper plane as 1300 mm, lower plane as 500mm, and radius distance of Y axis as 500mm. Then check the configured operating space along with the safe stop that occurs while directly teaching this operating space.

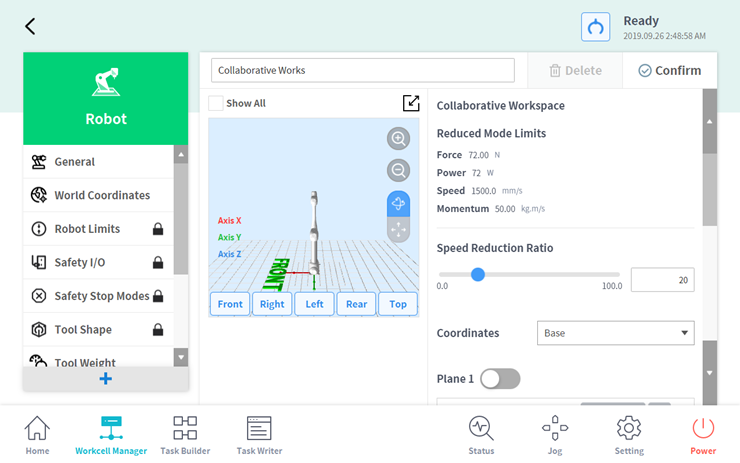

2.2 Collaborative Workspace: In a collaborative work space, a work space where robots and workers can work together at the same time, deceleration conditions can be set to reduce reaction forces, speed, etc that may occur during operation.

[Try it]

In the Collaborative Work Space function, use two points close to the XZ plane of the robot's base coordinate system to define Plane 1 and specify a selection point in the Y+ direction. Then check if deceleration occurs during robot operation.

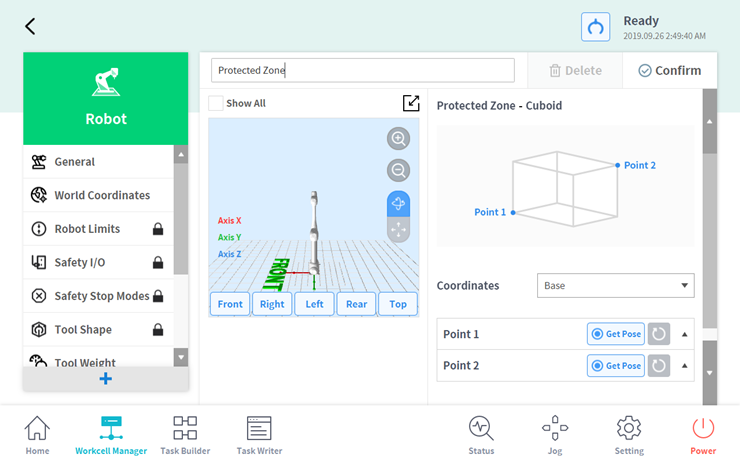

2.3 Protected Zone: If an area set as a protection section is intruded, the robot stops according to the safety-rated stop mode setting.

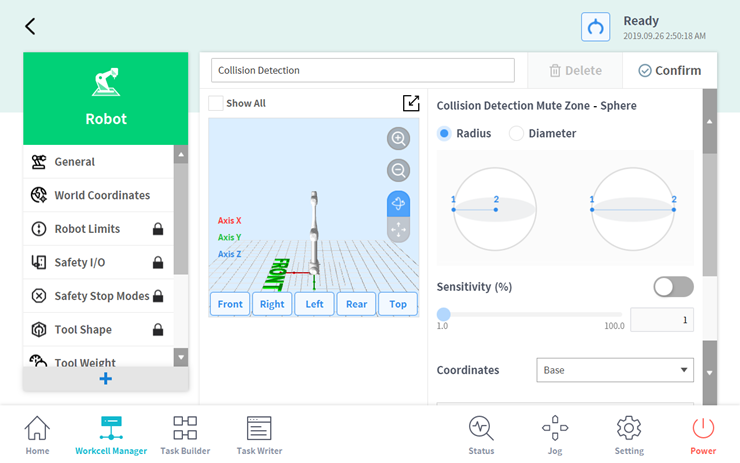

2.4 Collision Detection Mute Zone: If a section is set as disable collision detection section, collision detection can be disabled completely or collision detection sensitivity can be set.

[Try it]

In the Disable Collision Detection Section, set the geometry type as sphere, then select the radius condition and enter the location of the spherical surface and the center point respectively. Then check the configured disable collision detection section to see if collision detection is disabled during robot operation.

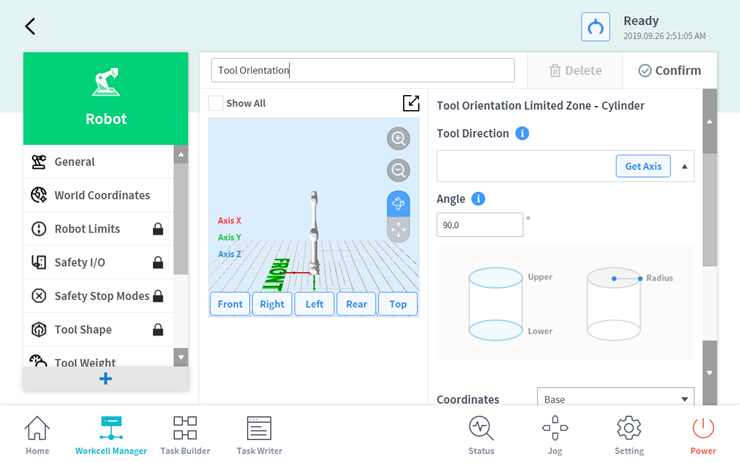

2.5 Tool Direction Limited Section: If the tool center point (TCP) exits the tool direction change limit section, the robot stops according to the safety setting configured in the Settings of the main

menu.

3. Troubleshooting Mode

Doosan robot provides safety recovery mode and zero-gravity motion for any problems that may occur during robot operation.

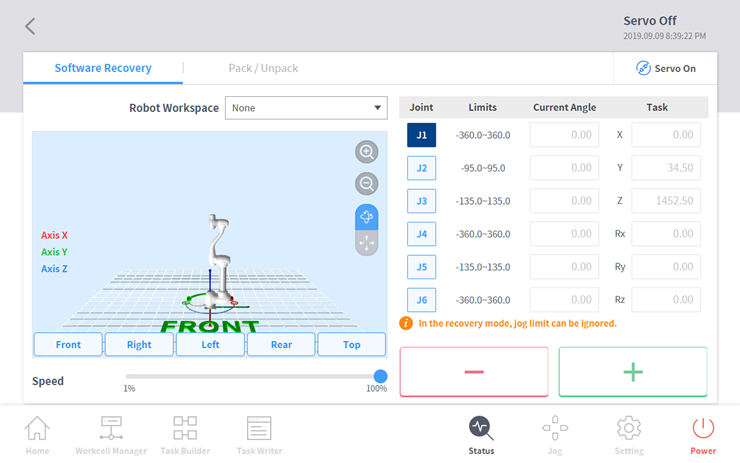

- Safety Recovery Mode: If there is a continuing error with a safety violation or if a robot is to be packed, the user can use Safety Recovery Mode to configure the position and angle of the robot. The method of use is similar to the jog function for joints, but in Safety Recovery Mode, the joint position limits specified in settings are ignored.

[Try it]

Enter the safe recovery function when the robot is in Servo Off status. Then press the Servo On button on the top right corner and change the robot to the desired position using the joint jog.

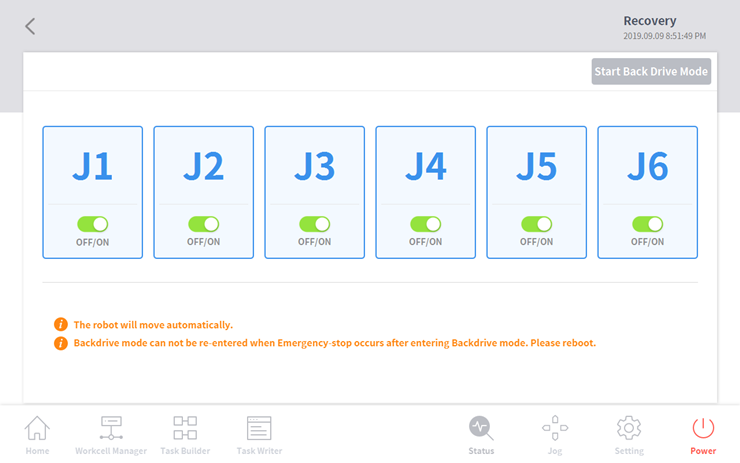

- Zero-Gravity Motion: The system controls the robot joint with only the brake and without power driving the motor. This function is used when the robot cannot return to normal with Safety Recovery Mode or Hand-guiding. For reference, this requires more power than direct teaching and the robot must be rebooted after using this function.

[Try it]

Enter the zero-gravity mode when the robot is in Servo Off status. Then press the zero-gravity mode start button and disengage the desired joint brake to move manually.

4. Summary

This course introduced the safety-related features provided by Doosan robot. Work space setting defines spaces in which functions such as operation, collaboration, and disable collision detection, etc can be utilized. Troubleshooting mode provides functions that can be used in problematic situations where the robot does not operate normally. Please refer to the Installation or User manual for more detailed information.

Recommended resources

- International Organization for Standardization, ISO 10218-1 & 2

- International Organization for Standardization Technical Specification, ISO/TS 15066

- Doosan Robotics Installation & User manual, https://robotlab.doosanrobotics.com

※ Doosan Robotics has copyright and intellectual property rights to all content and all designs shown in this material. Therefore, any use, copying, or dissemination of them without written permission from Doosan Robotics is prohibited. Please note that you will be held solely responsible for any improper use or alteration of the patent rights of Doosan Robotics.

Recommended Training Class

These learning opportunities can help you get started quickly.

Article

Programming with the robot’s PROFINET IO Device Function

Article

How to program with EtherNet/IP

Article

How to program using TCP/IP Socket